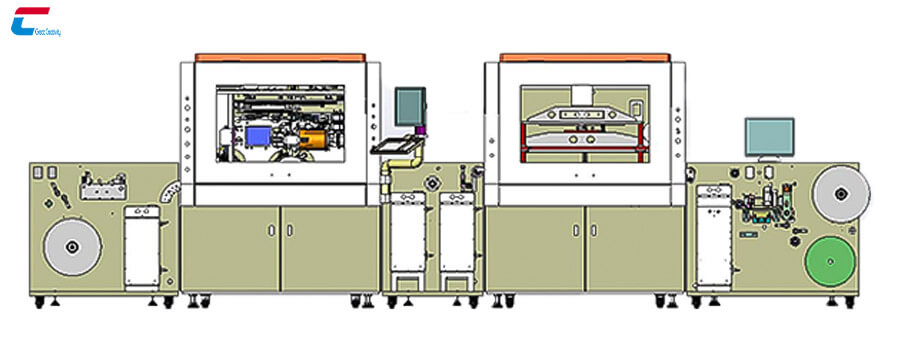

RFID Flip-Chip Machine-Single Track Narrowband

RFID(electronic label) flip-chip machine

- Equipment Track: Single line narrowband

- This equipment works for: All types of HF /UHF RF ID inlay.

- Production mode: Continuous production in roll.

- Chip and antenna connection and fixation mode: ACP

- Applicable base material: Various polyester (such as PET, PP, etc.) andsuitable paper, etc

- Applicable antenna types: Copper coated antenna, aluminum coated antennaand conductive ink printed antenna (thickness: 50-100 pm. Paper: 50-180g)

- Base material width: 35mm-150mm

- Wafer size: 8,12 inch

- Production pass rate: After adjusting the machine to stable working, batchproduction(HF/UHF)pass rate is more than 99.7%

Description

Single line RFID (electronic label) Flip-Chip equipment

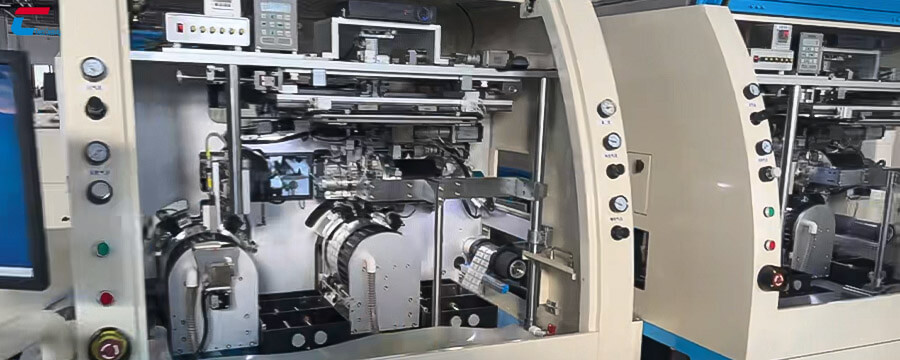

The single track narrowband RFID Flip-chip machine is the first independentlydeveloped and innovated special equipment in China for the production ofsingle-line RFID (electronic label). It is independently developed, innovated and produced by our company and has a number of invention patents andutility model patents. It accurately identifies RFID chip and flexible antenna through high-precision visual motion system, positioning them, and accuratelybinds tiny chips and antenna through high-speed and high-precision actuator.

The equipment main components

- Unwinding unit

- Glue spraying unit

- Bonding unit

- Visual unit

- XYwafer unit

- Buffering unit

- Curing unit

- Inspecting and marking waste unit

- Rewinding unit

- Liner unit

Basic technical parameters

| Function | Parameters | Function | Parameters |

|---|---|---|---|

| Footprint (mm) | 5800×1200 | Time to change the line | <2 hrs |

| Valer size | 8, 12 inch | Chips dimension (mm) | 0.24×0.35-1.0×1.0 |

| Chips thickness | ≥10μm | Valer enlargement | Φ2.0/mm/Φ300mm |

| UPH | 10000 pcs/h | Bonding accuracy | ±5μm |

| ACP glue method | spray glue | Gluing accuracy | ±5μm |

| Base material width (mm) | 35~150 | Glue amount control | ±10% |

| Mini. distance between bonding head center and base material edge | 15mm | Max distance between bonding head center and base material edge | 75mm |

| Types of antenna base materials | Pds. pp. paper | Antenna lines | single |

| Antenna longitudinal pitch | >14mm | Base material thickness | paper: 50g+180g |

| Chips type | HPUHF | Heating pressure range | 0.5N=4N |

| Heating temperature range | 0°-230° | Pressure control accuracy | ±0.11kg |

| Heating curing unit quantity | 56 curing unit | Temperature control accuracy | ±5° |

| UHF inspection system | Finland Voyantc | Way to mark waste | making by mechanical punch |

| Static elimination | Yes | Power voltage | AC380V±5% |

| Label core inner diameter | 76mm | Frequency/detectivity leakage current | 50 Hz/30mA |

| Label cell outer diameter | ≤400 | Machine power | 7KW |

| Compressed air MPA | 0.4 – 0.8 | Compressed air volume | 80L/min |

| Vacuum pressure kgs | -80 ~ +100 | Machine remotely possibility | Yes |

| Machine dimension (mm) | 5800 × 1200 × 2000 | Machine weight | 2.8 T |

Application Scenarios & Value Proposition

Single Line RFID Flip-Chip Equipment

Designed specifically for single-line RFID inlay and label manufacturing, this Single Track Narrowband RFID Flip-Chip Equipment delivers high precision, high yield, and stable mass production for industries where consistency and chip bonding accuracy are critical.

Key Application Areas

1. RFID Label & Inlay Manufacturing Plants

Ideal for manufacturers producing HF / UHF RFID electronic labels in large volumes.

The single-line structure ensures:

- Stable chip placement accuracy

- Consistent bonding quality

- Reduced material waste and rework rate

Perfect for factories focusing on cost control and yield optimization.

2. Apparel & Retail RFID Tag Production

Widely used in clothing, footwear, and fashion retail RFID labels, where flexible antennas and ultra-small chips require precise alignment.

The high-precision visual positioning system ensures:

- Accurate chip-to-antenna matching

- Reliable electrical performance

- High-speed continuous production

Supporting the fast-growing demand for item-level retail RFID tracking.

3. Logistics & Supply Chain Identification

Suitable for RFID labels used in:

- Warehousing management

- Pallet & carton tracking

- Asset identification

The equipment’s high-speed flip-chip bonding capability ensures stable output for logistics-grade RFID tags with strict performance requirements.

4. Smart Manufacturing & Industrial RFID

Applied in RFID labels for:

- Production line tracking

- Equipment identification

- Industrial asset management

The machine’s high repeatability and precision actuator system ensure long-term reliability in industrial environments.

Reviews

There are no reviews yet.