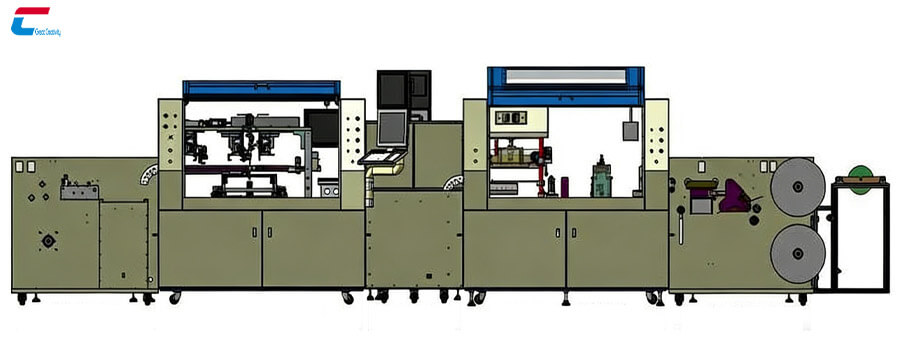

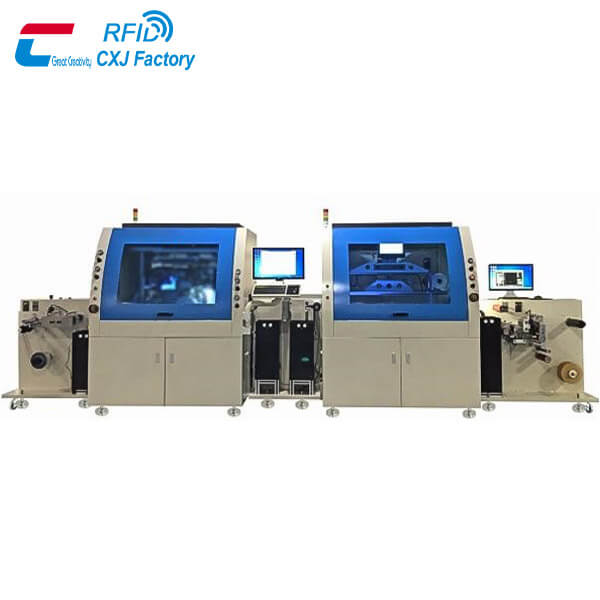

RFID Flip-Chip Machine-Multi-track Broadband

Multi-track Broadband RFID Flip-Chip Machine

- Compatible Chip Types: Various types of HF and UHF electronic label inlays

- Production Mode: Continuous roll-to-roll production

- Chip-to-Antenna Bonding Method: ACP(Anisotropic Conductive Paste)

- Compatible Substrate Materials: Various polyesters (e.g., PET, PP) and suitable papertypes

- Compatible Antenna Types: Copper-clad antenna, aluminum-clad antenna, andconductive ink printed paper antenna

(Antenna Thickness: 50-100um; Paper Weight:50-180 gsm) - Substrate Width: 100 mm to 370 mm

- Wafer Disk Size: 8-inch, 12-inch

- Production Yield Rate: Over 99.5% for mass production after adjustment andstabilization (for both HF & UHF).

Description

Multi-track Broadband RFID Flip-Chip Machine

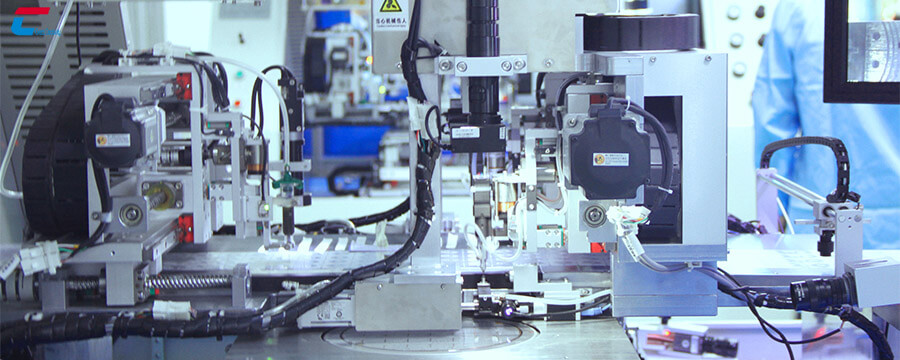

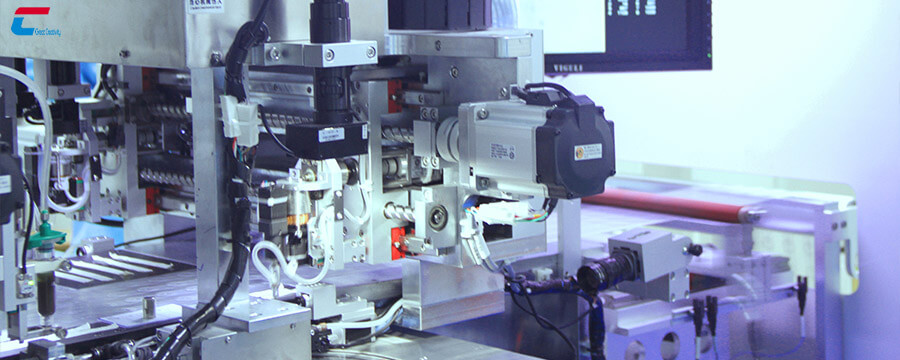

The Electronic Label (RFID) Packaging Machine is specialized equipment for packaging RFID chip inlays. It utilizes a vision recognition system to accurately identifyand position the RFID tag chips and flexible antennas (e.g., printed paper antennas).High-speed precision actuating mechanisms then achieve the precise bonding of the microchips to the antennas.

The equipment’s workflow includes the following functional modules: unwindingfeeding, dispensing, chip flipping and picking, chip placement(mounting), hot presscuring, inspection, marking, cutting, and rewinding. It is suitable for the precise packaging of various types of chip (HF/UHF)inlays.

Equipment Main Components

- Unwinding Module

- Dispensing Module

- Bonding Module

- Vision Module

- XY Wafer Handler

- Buffer Module

- Thermo-compression Curing Module

- Inspection and Marking Module

- Online Cutting Module

- Rewinding Module

- Wafer Dicing Tape Frame Unit

Basic technical parameters

| Function | Parameters | Function | Parameters |

|---|---|---|---|

| Footprint (mm) | 6700 × 1500 | Time to change the line | <3hrs |

| Wafer size | 8, 12 inch | Chips dimension (mm) | 0.4×0.4–2.0×2.0 |

| Chips thickness | ≥100 μm | Wafer enlargement | Φ240mm/Φ330mm |

| UPH Max | 10000 pcs/h | Bonding accuracy | ±50 μm |

| ACP glue method | spray glue | Gluing accuracy | ±50 μm |

| Base material width (mm) | 100~370 | Glue amount control | ±10% |

| Types of antenna base materials | Pet, pp, paper | Antenna lines | ≤10 |

| Antenna longitudinal pitch | >14mm | Base material thickness | paper: 50g–180g |

| Horizontal Antenna Pitch | >30mm | Heating pressure range | 0.5N–4N |

| Heating temperature range | 0° – 250° | Pressure control accuracy | ±0.1N |

| Heating curing unit quantity | 40 curing unit | Temperature control accuracy | ±5° |

| UHF inspection system | HF/UHF | Way to mark waste | Inkjet Marking |

| Static elimination | ≤2KV | Power voltage | Ac380V ±5 |

| Label core inner diameter | 76mm | Frequency/electricity leakage current | 50Hz/30mA |

| Label roll outer diameter | ≤400 | Machine power | 6.5KW |

| Compressed air MPA | 0.4 – 0.6 | Compressed air volume | 80L/min |

| Vacuum pressure kpa | −80°–100 | Machine removing possibility | Yes |

| Machine dimension (mm) | 6700 x 1500 x 1560 | Machine weight | 3.8 T |

RFID Electronic Label Packaging Machine – Applications

In today’s fast-evolving Internet of Things (IoT) era, RFID technology has become the backbone of various industries, including supply chain management, logistics, asset tracking, and access control. At the heart of this technological revolution is our RFID Electronic Label Packaging Machine, designed to precisely and efficiently package RFID tags. This machine ensures every tag is accurately bonded, meeting the diverse needs of industries worldwide.

Key Applications:

1. Logistics & Supply Chain Management

RFID technology is transforming logistics and supply chain management. By embedding RFID tags into goods and packaging, companies can streamline inventory management, automate distribution, and enable real-time tracking. Our RFID Packaging Machine ensures that each tag is perfectly bonded, enhancing automation and transparency in the supply chain.

2. Asset Management

RFID technology has become essential for asset management and equipment tracking in various sectors. Whether for managing assets in large enterprises or tracking medical equipment in hospitals, RFID tags provide precise and real-time data. Our packaging machine guarantees the reliability and precision of every RFID tag, ensuring the stability and efficiency of asset management systems.

3. Access Control & Security Systems

In access control and security systems, RFID technology offers an efficient and secure solution for fast and accurate identification of people and vehicles. By integrating RFID tags, companies can enhance security and streamline access control. Our machine supports multiple tag types and ensures high-quality RFID tags for secure and smooth operations in access control systems.

4. Smart Retail & Shopping

In the retail industry, RFID technology not only improves inventory management but also enhances the shopping experience for customers. By embedding RFID tags into products, retailers can monitor and track items in real-time, improving operational efficiency and customer service. Our RFID packaging equipment ensures high-speed and precise tag packaging, maintaining stability and quality in large-scale production.

5. Healthcare Industry

The healthcare sector leverages RFID technology for managing pharmaceuticals, patient identification, and equipment tracking. Our equipment supports a variety of substrate materials and antenna types, ensuring RFID tags meet the high standards required in the healthcare industry. This helps hospitals achieve precise asset management, drug traceability, and patient management.

Efficient & Precise Packaging for Industry Advancements

Our RFID Electronic Label Packaging Machine combines cutting-edge vision recognition systems with high-precision mechanical operations, ensuring that each chip and antenna pair is accurately bonded. This results in maximized production efficiency and high-quality tags. Whether you need to handle HF or UHF tags, our machine can meet large-scale production demands, providing high yield and consistent product quality (over 99.5%).

Why Choose Our Equipment?

- High Compatibility: Supports a wide range of antenna materials (copper, aluminum, conductive ink) and substrate types (PET, PP, paper), making it suitable for various industry needs.

- Precision & Stability: The ACP (Anisotropic Conductive Paste) bonding technology ensures high precision in chip-to-antenna bonding, delivering superior tag quality.

- High-Volume Production: Features roll-to-roll continuous production capabilities, making it ideal for large-scale manufacturing operations.

- Customizable Configurations: The equipment can be tailored to meet specific production needs, offering flexible solutions for various industries.

Reviews

There are no reviews yet.