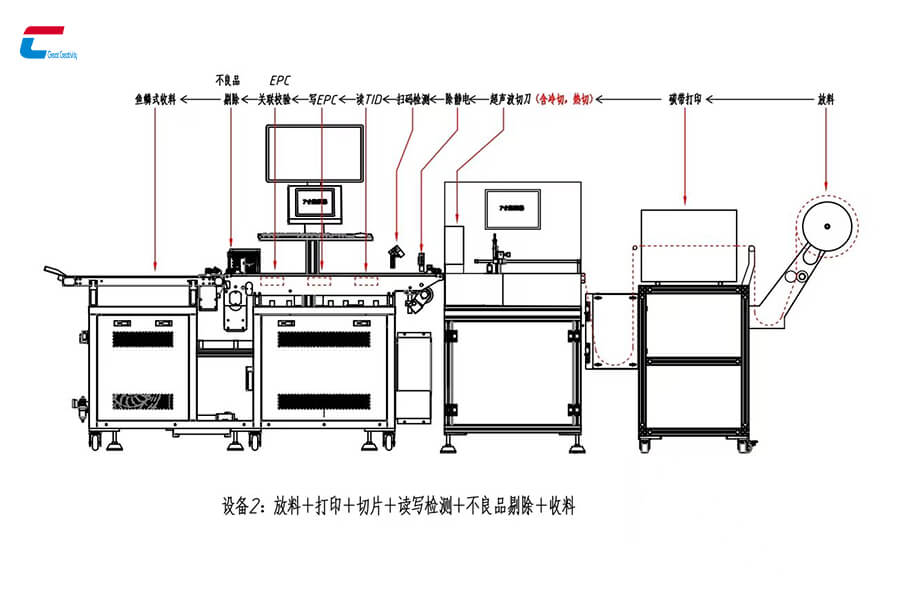

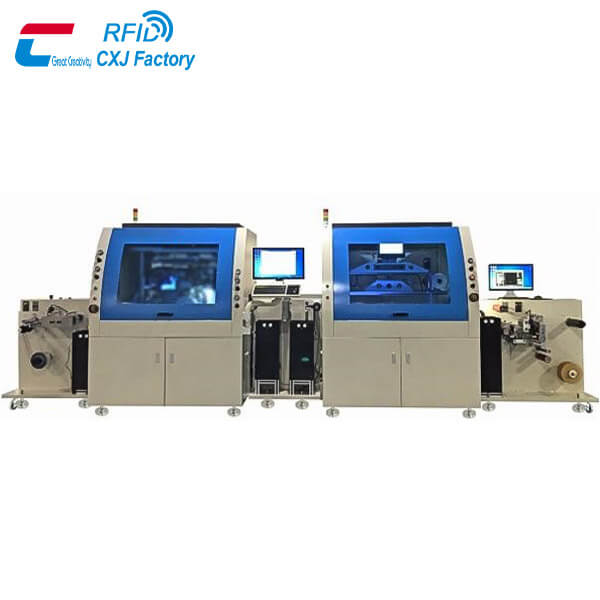

RFID Care Label Encoding Detecting Machine

RFID Care Label Encoding Detecting Machine

- Applicable Materials: Suitable for RFlD care labels (cotton,woven,taffeta, satin, nylon, and other care labels)

- Material Thickness: 0.2~0.5mm

- Feeding Accuracy:+0.5mm

- Label Width: 25~100mm

- Cutting Speed: 250~600 pieces/min (The actual speed dependson the label width)

- UHF Reading&Writing Speed: 150~600PCS/Min (The actualspeed depends on the chip, the label width)

- Core inner diameter of unwinding: 76±0.5mm

- External diameter of unwinding: MaxФ500mm

- Machine Size: (L)3950(W)750(H)980/1750mm

- Net Weight(approximate): 500kg

Description

Description

RFID Care Label Encoding Detecting Machine

The RFID Care Label Encoding & Detecting Machine is an automated system for high-speed encoding and quality verification of RFID-enabled garment labels. It ensures each label is accurately programmed and fully functional, supporting UHF/HF frequencies and integration with printing systems. Featuring precise inspection and real-time data logging, it is ideal for apparel manufacturers requiring reliable, scalable tagging for smart supply chain management.

Applicable Materials

Suitable for RFID care labels (cotton, woven, taffeta, satin, nylon, and other care labels)

| RFID Care Label Encoding Detecting Machine Specifications | |

|---|---|

| Basic Parameters | |

| Machine Size | (L)3950 × (W)750 × (H)980/1750 mm |

| Net Weight (approximate) | 500 kg |

| Rated Power (approximate) | 2.5 KW (For reference only) |

| Rated Voltage | AC220~240 V |

| Frequency | 50/60 Hz |

| Air Pressure | 0.5~0.8 MPa |

| Technical Specifications | |

| Applicable Materials | Suitable for RFID care labels (cotton, woven, taffeta, satin, nylon, and other care labels) |

| Material Thickness | 0.2~0.5 mm |

| Feeding Accuracy | ±0.5 mm |

| Label Width | 25~100 mm |

| Cutting Speed | 250~600 pieces/min (The actual speed depends on the label width) |

| UHF Reading & Writing Speed | 150~600 PCS/Min (The actual speed depends on the chip and the label width) |

| Core Inner Diameter of Unwinding | 76 ± 0.5 mm |

| External Diameter of Unwinding | Max. Φ500 mm |

| Function List | |

| Operating Mode | Continuous Feeding Mode |

| Cutting Method | Three methods for cutting: ultrasonic, cold cutting, and hot cutting |

| Unwinding Rolls | Independent motor for unwinding, automatically matches slicing speed |

| UHF Protocol | UHF RFID Protocols: EPC Gen2(ISO 18000-6C) |

| Read-write Mode | Support UHF labels TID reading and EPC encoding, and correlation verification of the encoded EPC data |

| Code Reading Inspection | Support reading variable data such as surface barcodes and QR codes and perform associated encoding |

| Defective Product Removal | Eliminate UHF tags that fail in surface reading or data encoding |

| Data Display and Export | Displays data such as the number of defectiveness, yield rate, TID, power settings, etc., and the data can be exported |

| Material Receiving | Count the labels that have been successfully read and encoded after slicing, and then sort them into stacks based on a certain quantity set by the configuration |

| Anti-static Function | Perform electrostatic treatment at the slicer discharge areas and label receiving areas to prevent chip damage caused by static electricity |

| Optional Items | |

| Visual Inspection | Read barcodes, QR codes, and OCR on the label surface, and detect defects on the label surface such as dirt and severe scratches |

Reviews (0)

Reviews

There are no reviews yet.