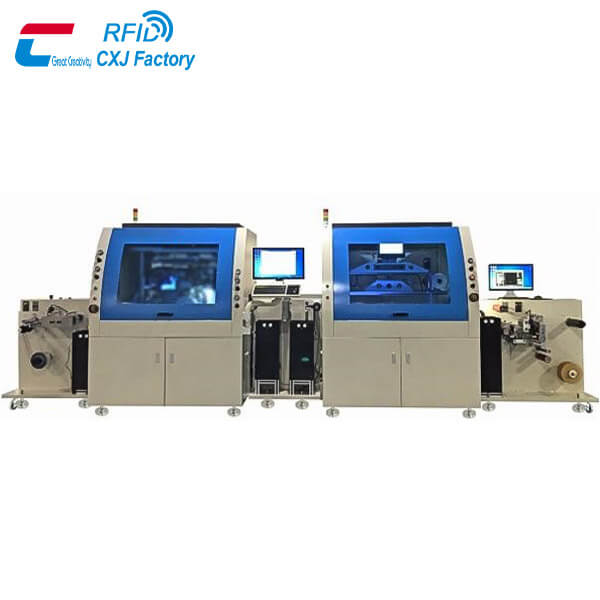

RFID Tag High-Speed Composite Die-Cutting Machine

RFID Tag High-Speed Composite Die-Cutting Machine

- Maximum operating speed of equipment (m/min): 100M/min

- Production speed: 0-80M/min (based on product material and process evaluation)

- Maximum material width (mm): 250

- Maximum unwinding diameter of Inlay (mm): 400

- Maximum coil diameter of material (mm): 600

- Glue speed: Normal glue application(100M/min) / Intermittent glue application (30-70M/min (determined by product jump distance)

- Coating accuracy: Normal glue application (15g+/-2g)/ Intermittent glue application(15g+/-2g, position accuracy+/-1mm)

- Maximum adhesive width (mm): 240

Description

RFID Tag High-Speed Composite Die-Cutting Machine

The speed of automatic laminating may reach to 60 meters per min. Assort with the special dry INLAY die-cutting module and hot melt glue mechanism, our machine is able to laminate dry & wet inlay label. Simultaneously if with high speed magnetic roller die-cutting module, we may help to implement the label after the process of die cutting and cards production.

FEATURES

• Dry inlay/wet inlay applied with inlay positioning cutting and vacuum drum institution. 3 sets high-speed rectify deviation Machine. 13 shaft servo system control.

• The main servo feeder institution.

• The finish paper is pre die-cutting by vacuum drum institution enable to have stabilized labeling.

• The ultromotivity constant tension institution of inlay label.

• The Label unwinding axial deviation to ensure stabilized label transfer.

• Specially install a non-stop lap changing device, making changing roll and paper receiving without stopping the machine become true.

• Automatically speed adjusted to track alignment.

• Lamination accuracy is±0.3mm (Subject to material printing accuracy, normally the general accuracy is in ±0.5mm).

| Parameter Name | Description / Value |

|---|---|

| Maximum Operating Speed | 100 m/min |

| Production Speed | 0-80 m/min (based on product material and process evaluation) |

| Maximum Material Width | 280 mm |

| Maximum Unwinding Diameter of Inlay | φ400 mm |

| Maximum Coil Diameter of Material | φ600 mm |

| Glue Speed (Normal Application) | 100 m/min |

| Glue Speed (Intermittent Application) | 30-70 m/min (determined by product jump distance) |

| Coating Accuracy (Normal Application) | ±1g/~2g |

| Coating Accuracy (Intermittent Application) | ±5g/~2g, Position Accuracy ±1mm |

| Maximum Adhesive Width | 240 mm |

| Dry Inlay Jump Distance | 12mm – 200mm, and less than material jump distance |

| Dry Inlay Cutting Accuracy | <±1mm (determined by product jump distance) |

| Dry Inlay Transfer Accuracy | <±1mm (determined by product jump distance) |

| Wet Inlay Transfer Accuracy | <±1mm (determined by product jump distance) |

| Composite Accuracy (Double-Layer Printed Materials) | <±0.4 mm |

| Outline Die-Cutting Accuracy | <±0.2 mm |

| Maximum Coil Weight | – |

| Machine Dimensions (L*W*H, approx.) | 4600 x 1700 x 2300 mm |

| Equipment Weight (approx.) | – |

| Rated Power | – |

| Rated Voltage | AC380-AC400V |

| Function Name | |

| Standard Configuration: INLAY Pasting | 1. Can achieve dry Inlay cutting and pasting (dual track) 2. Can achieve wet Inlay label peeling and transfer (single pass) |

| Dry INLAY Cutting and Pasting | Independent single/double track |

| Double Layer Printing Composite (Base Paper, Face Paper Composite) | Support |

| Mark-Free Point Bonding/Die-Cutting | Support |

| Multiple Sensor Scans, Automatic Cutting, Sheet Material Collection | Support |

| Inlay Bonding Direction | Support Inlay pasting, do not support Inlay reverse pasting |

| Tension Balance Mechanism | Support |

| Application Scope | For fabric labels, woven labels, washed labels, and adhesive labels, support for backing paper peeling and reuse |

| Double Die Cutting + Slitting | Support front/back cutting |

| Independent Functional Blocks | Equipped with multiple sets of sensors, can be used for cutting, pasting, and die-cutting, and can operate independently or in conjunction. |

| Glue Application Function | Apply adhesive to the base paper and surface paper |

| Static Elimination | Eliminate static electricity in Inlay |

| Sheet Material Conveying | After die-cutting, the sheet material is counted and collected by first and second level conveyor belts |

| Data Transmission, Intelligent Factory System Integration | Reserved interface for docking with MES system and other intelligent factory management systems for data uploading |

| Intelligent Software System | New product software feature requirements, remote online upgrade, saving upgrade cycle |

| Material Cut-Off Alarm | Material belt breakage, equipment alarm |

| Product Processing Capability | According to different needs, corresponding mechanism components (optional) can be added to achieve products such as hang tags, stickers, woven labels, washed labels, aviation luggage tags, flexible metal resistant labels, multi-layer asynchronous bonding, etc. |

Reviews

There are no reviews yet.